Samsung has been working on improving its 4nm chip-making process for a while now, and it seems that the company is making significant progress. According to Sammobile and 9to5google, Samsung’s 4nm process is now on par with TSMC’s, and the company is confident that it will beat TSMC’s 4nm production capacity soon. Samsung’s steady progress in improving its 4nm chip yield may earn the company new orders from key clients such as Qualcomm and NVIDIA.

According to TrendForce, the company’s contract chip unit is gaining market share. It now appears that the huge funding of its foundry business is now paying off. In addition, Samsung is expected to start mass production of chips using 4nm process technology in the United States by the end of 2024. It will be ahead of TSMC’s Fab 21 plant in Arizona.

In a special speech at the Seoul National University, Samsung co-CEO Kyung Kye-hyun said the company is optimistic about its position in the semiconductor market. He also claims that the company is ready to compete more aggressively than before.

Samsung to Mass Produce Third-Gen 4nm Semiconductor Chips Soon

Samsung is all set to begin mass production of the third-gen 4nm chips during the first half of 2023. The company has invested $3.8 billion to increase its 4nm production factories to improve yields. Samsung’s Pyeongtaek location spans nearly 2.89 square kilometres. It is as wide as the total space of chip manufacturing sites in Hwaseong and Giheung combined. This new facility will help Samsung to increase its production capacity and meet the growing demand for its 4nm chips.

Gizchina News of the week

Samsung’s upcoming fab near Tyler, Texas, will be the company’s first leading-edge production facility in the U.S. in years. Samsung has high hopes that it will enable it to meet the needs of its many U.S. customers and challenge Intel and TSMC’s foundry services.

According to the report, if all goes according to plan, the new factory of Samsung’s 4nm process technology (SF4E, SF4, SF4P, SF4X and SF4A) will start mass production by the end of 2024. While this is unlikely to have an immediate impact on the foundry market, Samsung can arguably beat TSMC to the punch with its 4nm process in the US. However, Samsung Foundry will still lag behind Intel Foundry Services, which plans to start producing chips at its 20A (2nm class) node in 2024 and its 18A (1.8nm class) node in 2024-2025 produce chips.

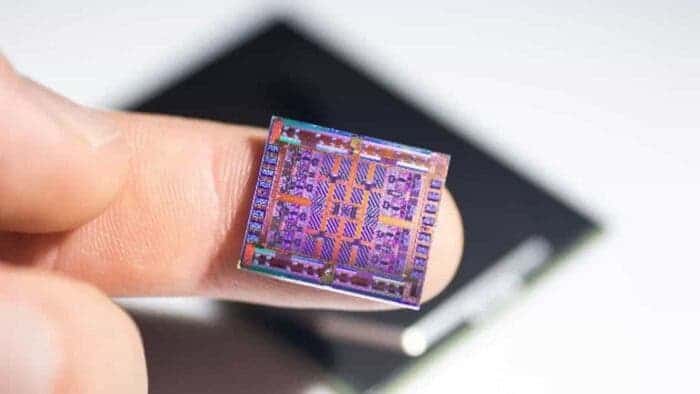

Samsung Foundry’s 4nm-Class Process Technology Yield Is Now Higher Than 75%

Samsung Foundry’s 4 nm-class process technology yield is now higher than 75%. This is a significant improvement from the past, and it shows that Samsung is making steady progress in improving its 4nm chip yield. The “yield” in chip production refers to the number of chips produced on one wafer compared to the maximum number technically possible. A higher yield means that more chips can be produced from a single wafer, which can help to reduce the cost of production and increase profitability.

According to TrendForce data, Samsung’s foundry’s market share in the foundry chip manufacturing market soared from 9.9% in the first quarter to 11.7% in the second quarter of 2023, with revenue reaching $3.234 billion, up from $2.757 billion in the first quarter. While TSMC maintained its dominance, its market share fell to 56.4% with revenue of $15.656 billion.

Conclusion

Samsung’s steady progress in improving its 4nm chip yield is a positive sign for the company. The company is confident that it will beat TSMC’s 4nm production capacity soon, which will help it to win new orders from key clients such as Qualcomm and NVIDIA. Samsung’s investment in its 4nm production factories and the new Pyeongtaek facility will help the company to increase its production capacity and meet the growing demand for its 4nm chips. With a yield of over 75%, Samsung is making significant progress in improving its 4nm chip yield, which will help to reduce the cost of production and increase profitability.